Step inside Ferguson’s new Market Distribution Facilities (MDCs) and you will note a future the place robots work collectively, sorting and choosing merchandise in two not too long ago opened automated distribution facilities.

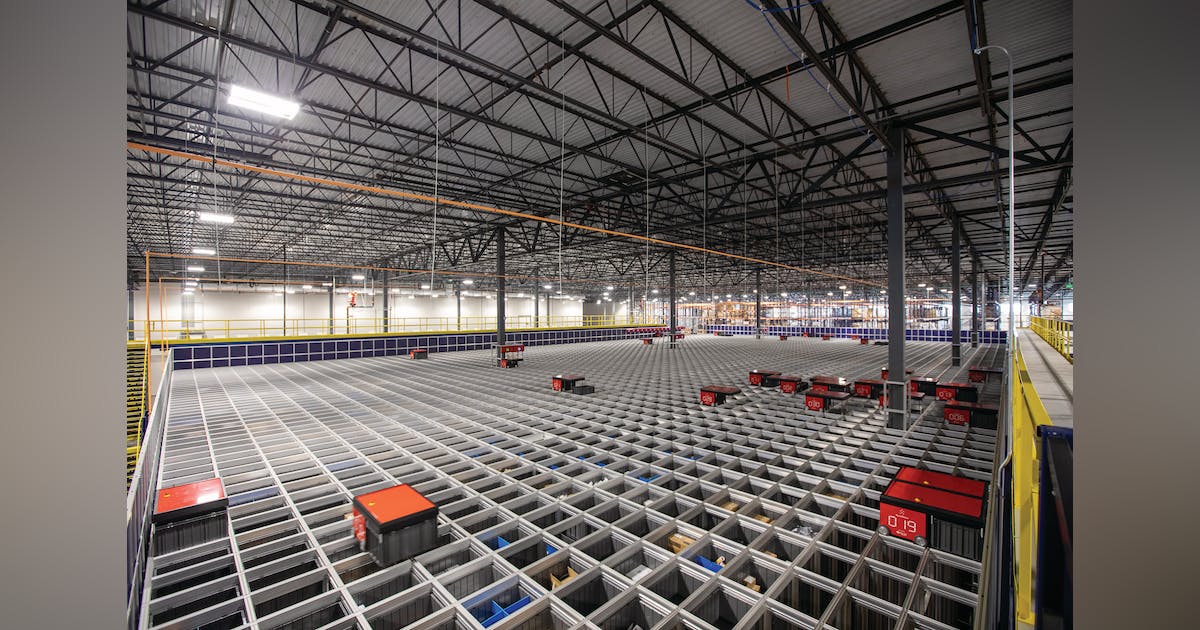

The MDCs, situated exterior of Denver, in Aurora, Colorado and outdoors Phoenix in Chandler, Arizona, home the modern know-how working a set of “robots” that perform duties inside a bodily grid. One supercomputer manages every robotic’s motion, automating the monitoring, gathering, organizing and pulling of orders from 1000’s of bins stacked on prime of each other inside the facility. By the use of instance, the Aurora facility’s 16,000-square-foot system holds 49,000 bins and 26,000 merchandise.

Supplementing a human workforce with the brand new robotic know-how permits distribution facilities to course of extra orders in a shorter period of time. That’s welcomed information for purchasers and companies that depend on distribution facilities for the supply of their items rapidly and effectively. Moreover, robots ship power consumption financial savings—serving to Ferguson obtain its carbon discount objectives.

Productiveness and Effectivity

“The robots work all day and evening, saving on conventional warehouse prices and permitting us to satisfy orders rapidly for sooner same-day product availability,” says SVP of Provide Chain Michael Jacobs. “The system additionally decreases handbook dealing with of supplies.”

Along with the automation know-how, the amenities had been constructed with effectivity on the forefront. Ferguson makes use of a particular machine to make customized bins based mostly on the size of every product to attenuate packaging waste. Every constructing options LED movement detector lighting methods to preserve electrical energy.

Will Robots Exchange People?

However robots cannot do the whole lot people can. Higher than any robotic, Ferguson associates are extremely expert and carry out the advanced duties to satisfy our clients’ wants. Actually, the Chandler facility added 75 new jobs to the realm and employs roughly 200 associates. So, whereas robots could carry out some features of the job, there’s nonetheless a necessity for associates in distribution facilities to run the know-how, give attention to advanced duties and ship high quality customer support.

Ferguson plans to construct two or three new MDC amenities yearly over the subsequent a number of years creating alternatives for jobs and modern, sustainable practices.