UPDATE: March 20, 2023: Samsung elevated the price of its Taylor, Texas, manufacturing unit to over $25 billion final week from its initially deliberate $17 billion. The South Korea-based electronics firm attributes the $8 billion hike to excessive inflation, in keeping with Reuters.

That continues to contribute to each lingering general supplies value inflation and provide chain challenges throughout the development business.

Sources mentioned Samsung has already spent about half of the $17 billion initially deliberate for the Taylor plant, in keeping with the Reuters report.

The unique story follows beneath.

Dive Temporary:

- Samsung Electronics has tapped Mississippi-based Yates Building as common contractor to construct its $17 billion chip plant in Taylor, Texas, situated about 30 miles northeast of Austin, the Austin Enterprise Journal reported. It’s the South Korean firm’s largest-ever funding made within the U.S.

- The 1,200-acre undertaking is anticipated to cowl 6 million sq. toes when accomplished. The corporate needs to interrupt floor in 2022 with the intention to start operations within the second half of 2024, in keeping with a Samsung press launch.

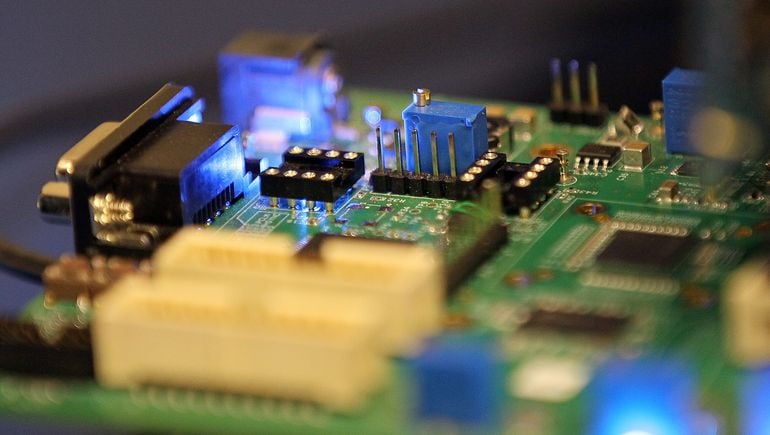

- Samsung mentioned that the brand new manufacturing unit will manufacture superior laptop chips, or superior logic semiconductors, that are utilized in telephones, computer systems, automobiles and different electronics.

Dive Perception:

Yates Building has labored on large manufacturing plant tasks within the U.S. and Mexico for Volvo, Toyota and Nissan. The Samsung undertaking will embrace buildings, property enhancements, equipment and tools, in keeping with the discharge.

Semiconductor shortages have roiled many industries up to now 12 months, arising from provide chain disruptions pushed by the COVID-19 pandemic, and are prone to be prolonged by the struggle in Ukraine which is choking availability of key supplies. Samsung is one in every of many corporations trying to geographically diversify its semiconductor manufacturing operations.

“With larger manufacturing capability, we can higher serve the wants of our prospects and contribute to the steadiness of the worldwide semiconductor provide chain,” mentioned Kinam Kim, vice chairman and CEO of Samsung’s Electronics Gadget Options Division, within the press launch.

President Joe Biden mentioned in February that home semiconductor manufacturing is a precedence for his administration, and put ahead a sequence of federal funding and tax incentives for semiconductor manufacturing, together with the $52 billion CHIPS Act, with the intention to spur extra manufacturing within the U.S. Whereas the CHIPS Act handed in January 2021, congress has but to move a invoice funding its provisions. Nevertheless, high Democrats mentioned Tuesday they’re hopeful a deal might come subsequent week.

Within the meantime, different American semiconductor manufacturing unit tasks are transferring forward, together with Texas Devices’ construct in Sherman, Texas, and Intel’s two vegetation in Chandler, Arizona